-

Telecom Steel Tower

-

Transmission Steel Tower

-

Camouflaged Cell Towers

-

Galvanised Street Light Pole

-

Lattice Steel Towers

-

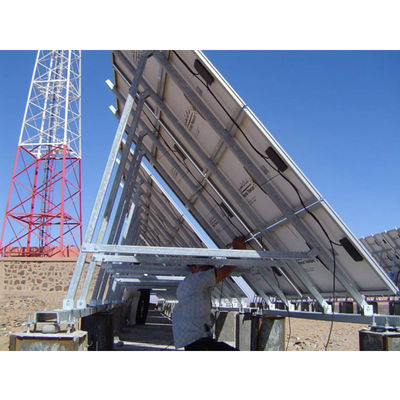

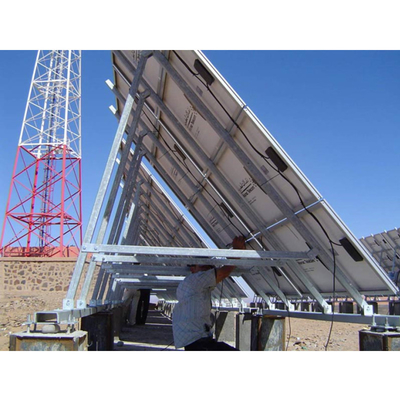

Solar Panel Support Structure

-

Galvanized Steel Structures

-

Traffic Signal Light Pole

-

Steel Tubular Pole

-

Rooftop Antenna Tower

-

High Mast Light Tower

-

Guyed Wire Towers

-

CCTV Camera Poles

Q235 Galvanized Steel Solar Panel Mounting Structure For Auto Part Industry

| Place of Origin | Guangzhou, China |

|---|---|

| Brand Name | Guangxin |

| Certification | ISO9001 |

| Model Number | GX-1017 |

| Minimum Order Quantity | 1 set |

| Price | USD11 per kg |

| Packaging Details | In Bundles and fasten with steel strips or by wooden pallets |

| Delivery Time | 20-25 days |

| Payment Terms | Western Union, L/C, T/T |

| Supply Ability | 100 sets per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Usage | Q235 Material Galvanized Steel Solar Panel Mounting Structure | PV Module | Framed |

|---|---|---|---|

| Tilt Angle | Up To 60° | Material | Aluminum AL6005-T5 |

| Snow Load | 1.5kn/sqm | Wind Load | Up To 60m/s |

| Application | Solar Panel System | Soil Class | 4 |

| Warranty | 10years | ||

| Highlight | Galvanized Steel Solar Panel Mounting Structure,Q235 Solar Panel Mounting Structure |

||

Q235 Material Galvanized Steel Solar Panel Mounting Structure

Specification of Solar Panel Support Bracket:

| Material: | Aluminum 6063 / Steel Q235 |

| Product: | Custom metal parts as customers' ideas, drawings or samples |

| Manufacturing Equipment: | CNC, sawing, deburring, punching, tapping, chamfering machines |

| Surface Treatment: | HDG(hot dipped galvanized ),Pre-galvanized,Electrical-galvanizing(yellow or white),powder coating(Black,Green,White,Grey,Blue)etc. |

| Usage: | LED light industry, solar panel industry, sanitary ware industry, auto part industry, heat sink industry and etc. |

| Dimensions: | Customized |

| Lengths: | Either 20FT or 40FT or cut into the length according to clients' requirements |

| QC: | 100% Strict Inspection For Every Processing |

| Service: | One-stop Service:Custom Design, Fabrication, Assembly And Delivery |

| Thickness: | Above 0.7mm or customized |

1 Guangxin mounting system compatible with most of the major framed and frameless PV modules on the market.

2. Products were designed by the experienced designers which have the systematic design, stable structure, mature technology, can reduce the difficulty of the installation on the most conditions.

3. The pre-assembled design of the highest level in factory simplifies construction site work to the largest degree and therefore installation is simple and quick. It can effectively improve construction efficiency, shorten construction period and reduce construction costs.

4. Reduced installatin times due to high pre-fabrication level; Minimized assembly time and effort (up to 40%).

5. The racking systems can withstand extreme weather condition. The main supporting components have also been tested to ensure their structure and bearing capacity.

6. The mounting system is suitable for various kinds of project, including residential project, commercial project, utility project and so on.