-

Telecom Steel Tower

-

Transmission Steel Tower

-

Camouflaged Cell Towers

-

Galvanised Street Light Pole

-

Lattice Steel Towers

-

Solar Panel Support Structure

-

Galvanized Steel Structures

-

Traffic Signal Light Pole

-

Steel Tubular Pole

-

Rooftop Antenna Tower

-

High Mast Light Tower

-

Guyed Wire Towers

-

CCTV Camera Poles

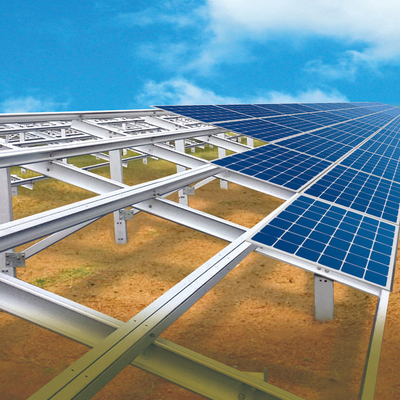

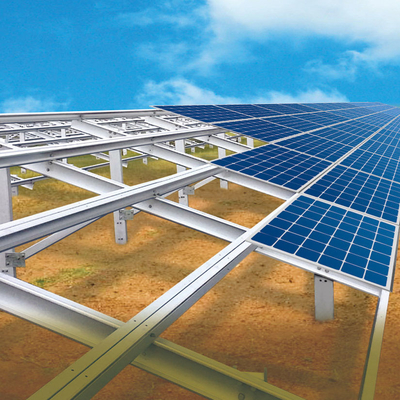

Galvanized Steel Solar Panel Support Structure Photovoltaic System Steel Frame

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Structural Low Carbon Mild Steel | Surface Finish | Hot Dip Galvanization |

|---|---|---|---|

| Design | Customized To Drawings | Dimensions | Customized To Drawings |

| Application | Solar Power Farms, Photovoltaic Power Plants |

Galvanized Steel Solar Panel Support Structure Photovoltaic System Steel Frame

As a renewable and sustainable engergy, solar power is more and more popular and applicable on the world, solar panel photovoltaic systems are very important to build a power station. In order to support the solar panels, a good steel structure is required.

We're professional manufacturer of all kinds of steel structures including telecom towers, power transmission towers, wind turbine towers, solar panel structures, traffic gantry frames and other related products. We can fabricate these steel works according to customer's designs, drawings and requiements.

The solar panel photovoltaic support structures are genereal made of I-beams, C-type beams, CHS, SHS and RHS beams and other steel materials.

![]()

Technical Specifications of Galvanized Steel Materials for making solar panel support structures

| Galvanized Steel structures | ||

| 1. Material | ||

| Weldable Structural Low Carbon Steel Plates or Tubes | ||

| 2. Grade | Main structure | Braces |

| GB/T1591:Q345B | GB/T 700:Q235B | |

| ASTM A572 Gr50 | ASTM A36 | |

| EN10025: S355JR, S355J0,S355J2 | EN10025: S235JR, S235J0,S235J2 | |

| 3. Design Wind Speed | Up to 250 km/h | |

| 4. Allowable deflection | 0.5 ~1.0 degree @ operational speed | |

| 5. Tension strength | 470~630 MPa | 360~510 MPa |

| 6. Yield strength | 355 MPa | 235 MPa |

| 7. Elongation (%) | 24 | 20 |

| 8. Impact strength KV (J) | 27(20°C)---Q345B(S355JR) | 27(20°C)---Q235B(S235JR) |

| Bolts & Nuts | ||

| 9. Grade | Grade 4.8, 6.8, 8.8 | |

| 10. Standards for mechanical properties | ||

| 10.1 Bolts | ISO 898-1 | |

| 10.2 Nuts | ISO 898-2 | |

| 10.3 Washers | ISO 6507-1 | |

| 11. Standards for Dimensions | ||

| 11.1 Bolts | DIN7990, DIN931, DIN933 | |

| 11.2 Nuts | ISO4032, ISO4034 | |

| 11.3 Washers | DIN7989, DIN127B, ISO7091 | |

| Welding | ||

| 12. Method | CO2 Shielded Arc Welding & Submerged Arc Welding(SAW) | |

| 13. Standard | AWS D1.1 | |

| Galvanizing | ||

| 14. Galvanization standard of steel sections | ISO 1461 or ASTM A123 | |

| 15. Galvanization standard of bolts and nuts | ISO 1461 or ASTM A153 | |