-

Telecom Steel Tower

-

Transmission Steel Tower

-

Camouflaged Cell Towers

-

Galvanised Street Light Pole

-

Lattice Steel Towers

-

Solar Panel Support Structure

-

Galvanized Steel Structures

-

Traffic Signal Light Pole

-

Steel Tubular Pole

-

Rooftop Antenna Tower

-

High Mast Light Tower

-

Guyed Wire Towers

-

CCTV Camera Poles

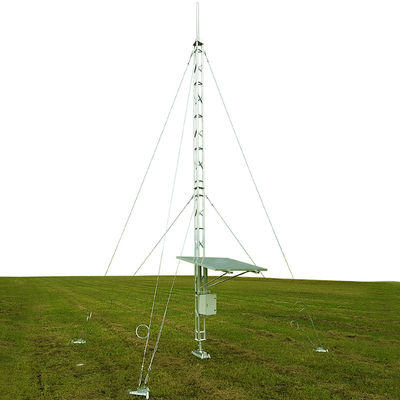

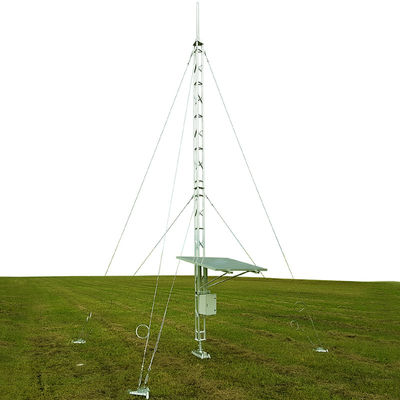

High Mast 30m 60m Guyed Wire Telecom Steel Tower For Communication

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Galvanized Steel Guyed Wire Tower | Material | Weldable Structural Angle Steel Plates Or Pipes |

|---|---|---|---|

| Surface Finish | Hot Dip Galvanization | Height | 30m To 60m Or Customized Height |

| Material Grade | GB Q235, Q345, Q355 Or Specified Grade | Yield Strength | 235~355MPa |

| Galvanized Thickness | 65~85 Microns | Design | 1-5 Platforms With Mounting Brackets |

| Wind Load | 0.36-1.0kN/sqm | Lifespan | 20-50 Years |

| Highlight | 60m Telecom Steel Tower,ISO9001 Telecom Steel Tower,60m high mast tower |

||

30m 60m High Mast Guyed Wire Telecom Steel Tower For Communication

30-60m High Mast Guyed Wire Galvanized Steel Communication Tower

Bipod, Tripod or Lattice Rooftop and Ground Mounted Guyed Wire Galvanized steel Communication Tower, Antenna Tower, Radio Tower and TV tower, Power Transmission and Distribution Tower

Specifications of 3 Legged Tubular Steel Lattice Tower

| Material | Tubular steel pipes, angular steel plates, flat steel plate or solid steel bars, bolts and nuts |

| Steel Type | Weldable low carbon structural steel |

| Steel Grade | GB Q235, Q345, BS 4360, ASTM A36 etc. |

| Yield Strength | Fy≥235MPa |

| Tensile Strength | Fu≥400MPa |

| Elongation | σ≥20% |

| Surface Finish | Hot dip galvanization |

| Galvanized layer | T≥65μm |

| Height | 20m to 100m, customized to requests |

| Design | 3 legs self-supporting or free standing lattice tower |

| Structure | 1 to 5 platforms, each platform comes with 4 to 6 brackets for mounting antennas or specified number of brackets for mounting antennas, microwaves, RRUs and other devices. |

| Supply mode | CKD(Complete Knocked Down), SKD(Semi-Knocked Down), DKD(Direct Knocked Down) |

| Fixing/Fastening | Bolts and nuts, connecting flanges |

| Configuration | Foundations/anchoring bolts, tower sections, 1-5 platforms (optional), mounting brackets, ladder, anti-fall safety system, lightning rod, earthing plate etc. |

| Wind Load | 0.35-1.0kN/sqm |

| Lifespan | 20-50 years |

| Warranty | 3 years |

| Applications | GSM/3G/4G/5G/FM radio antennas, microwaves, telecom stations |

SST: Self-supporting Steel Tower

Self-supporting steel tower is the most popular tower for communication or power transmission and distribution applications. It’s generally designed for 3 legs or 4 legs, composed of galvanized tubular steel pipes and angular steel plates by welding and fastening with bolts and nuts. With height of 35m to 100m, the steel lattice towers are widely used for mounting communication macrocell stations and power transmission or distribution wires or cables.

![]()

50m Hight Mast 4 legged Angular Steel Lattice Communication Tower with 2 platforms

4 legged self-support steel lattice tower is generally made of angular steel plates and flat steel plates. The 4-leg lattice tower is generally divided into several sections and the sections are connected by flat connecting plates with bolts and nuts. Each tower section is made of angle steelt plates and flat plates. All the steel plates are prefabricated with cutout, holes and hot dip galvanization.

Specifications of 4 Legged Angular Steel Lattice Tower

| Material | Angle steel plates, flat steel plate, bolts and nuts |

| Steel Type | Weldable low carbon structural steel |

| Steel Grade | GB Q235, Q345, BS 4360, ASTM A36 etc. |

| Yield Strength | Fy≥235MPa |

| Tensile Strength | Fu≥400MPa |

| Elongation | σ≥20% |

| Surface Finish | Hot dip galvanization |

| Galvanized layer | T≥65μm |

| Height | 20m to 100m, customized to requests |

| Design | 4 legs self-supporting or free standing lattice tower |

| Structure | 1 to 5 platforms, each platform comes with 4 to 6 brackets for mounting antennas or specified number of brackets for mounting antennas, microwaves, RRUs and other devices. |

| Supply mode | CKD(Complete Knocked Down), SKD(Semi-Knocked Down), DKD(Direct Knocked Down) |

| Fixing/Fastening | Bolts and nuts, connecting plates |

| Configuration | Foundations/anchoring bolts, tower sections, 1-5 platforms (optional), mounting brackets, ladder, anti-fall safety system, lightning rod, earthing plate etc. |

| Wind Load | 0.35-1.0kN/sqm |

| Lifespan | 20-50 years |

| Warranty | 3 years |

| Applications | GSM/3G/4G/5G/FM radio antennas, microwaves, telecom stations. |

![]()

70m High Mast 4-leg Anglular Steel Mobile Communication Tower With 3 Platforms and Antenna Brackets

The structure of 4 legged steel lattice communication tower is generally composed of foundation anchoring bolts (cage frames), sections of tower body, 1 to 5 platforms, mountning brackets, lightning arrest/protection rod, ladder, earthing plates, anti-fall safety system (cage structure) and fasteners (such as clamps, clips, bolts and nuts etc.). The design, structure and height of telecommunication towers can be customized according to requirements and drawings.

Similar Galvanized Steel Communication Towers

3 legged self-support steel lattice tower is generally made of tubular steel pipes as main structure (you can tell it as tower legs or body) and angular steel plates or pipes as sub-frame (horizontal and vertical bracings). The lattice tower is generally divided into several sections and the sections are connected by flange plates with bolts and nuts. Each tower section is made of tubular steel pipes and angular or flat steel plate, sometimes the tower is made of completely steel pipes or some bracings are made from solid steel bars.

The sections of tubular steel lattice tower completely made from steel pipes are generally welded in factory by 5m or longer lattice parts, each section is welded with flange plates for connection among tower sections. When you install the tower, you need to construct foundations with anchoring bolts frame (someone calls it steel cage frame) and concrete. The tower is fixed to foundations via flange plates with bolts and nuts. This kind of tubular steel lattice tower is easier for installation and very solid and strong, but the cost is a little higher and more costly for transportation because all the tower sections are welded in big parts which take more room in the truck or container.

So the most popular 3 legged steel lattice tower is made from tubular pipes and angular steel plates. The steel pipes are made for tower legs, angular steel plates are made for bracings (support members) and flate steel plates for connectors. The steel pipes are welded with flanges at each end for connection. All the parts of tower are prefabricated in CKD (completel knocked down) steel members ready for installation. When you install the tower, just fix the steel pipes to foundations by bolts and nuts and then connect the angular steel plate bracings to the pipes via welded connecting plates with bolts and nuts. In CKD way of fabrication, the cost is lower and shipping cost is also much lower because you can ship more materials in a container or truck.